Hot Springs, AR 71913

Little Rock, AR 72209

Food Service & Technology in Hot Springs, Little Rock, & All of Arkansas

Quality Control, Investigation, & Analyses

In the food industry, maintaining top-notch quality is paramount. Ensuring the freshness of food ingredients at every stage - from processing and packaging to storage and transportation - until they reach the store shelves is crucial. The Quality Control Manager understands that a strong defense is the best offense, a principle we firmly believe in as well.

However, even the most robust systems and defensive strategies can develop vulnerabilities. If products are falling short of expectations, it likely indicates that the cleaning and sanitizing protocols are not effectively safeguarding the process. This is where we come in.

Our seasoned team of experts can pinpoint areas of contamination that may have been overlooked. We will also work with you to elevate your Quality Assurance/Quality Control (QA/QC) Program, enhancing your ability to manage contaminants effectively.

Within the framework of the sanitation monitoring program, ATOKA employs traditional swab testing for quality assurance purposes. However, it is our extensive expertise that elevates our monitoring surveys to a superior standard. Additionally, we are equipped to assist in the development of your MIcro-Plan.

- HACCP Inspections & Reviews

- Sensory Panel Evaluations

- Plant Inspections & Sanitation

- Quality Assurance & Control Testing

- Comprehensive Microbiology Lab Services

- Studies on Shelf-Life

- Challenges Studies Conducted

- Screening for Spoilage & Pathogens

- Detection of Toxins & Plant Diseases

- Taste Test Studies with Statistical Accuracy

- Aerobic Plate Counting

- Counting Coliforms/E. Coli

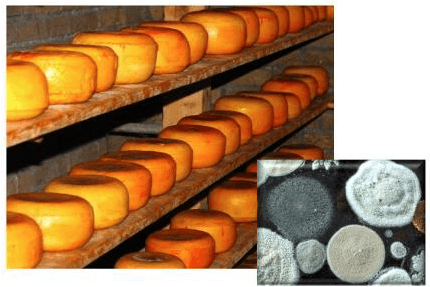

- Yeast & Mold Count Analysis

- Identification of Bacteria & Mold

- Counting and Identification of Algae

- Fecal Streptococcus Counting

- Microscopic Identification Services

- Pathogen Detection

- Salmonella Identification Services

- Kaufman-White Species Sero-typing Scheme

Shelf-Life Studies

The durability of a food product, known as its shelf-life, is influenced by both the environmental conditions it faces and the components that enhance its quality. Shelf-life is the point at which a product should no longer be sold to consumers due to factors such as nutrient loss, changes in flavor, color, taste, or undesirable texture development.

Traditional shelf-life assessments can be time-consuming, often taking 12-24 months to obtain results. To expedite this process, Accelerated Shelf-Life Testing (ASLT) is a scientifically accepted method that predicts how food products will fare under storage conditions that hasten deterioration. ATOKA specializes in ASLT studies for food manufacturers, aiding in the precise determination of shelf-life. By collecting data and applying them to a kinetic plot (Arrhenius Model), we can forecast when deterioration will begin, significantly reducing the wait time for results.

We assist you in maximizing your time, saving on costs, and enhancing the quality of your product.

Sensory Evaluation of Foods

Novel "ready-to-serve" product formulations created for consumer consumption undergo thorough regional taste studies to ensure they meet specific criteria before entering the market. These criteria are meticulously crafted to assess various sensory attributes among 25-50 individuals who accurately represent the local demographic distribution.

Following the selection of evaluation methods, a trained panel rates the product against a standard using a detailed questionnaire. The feedback is collected and analyzed through statistical methods such as nonparametric techniques, binomial-based analysis, or analysis of variance, aligning with the sensory test protocol.